While some costumers may find a perfect fit in one of the "default" pattern sizes, it is somewhat unlikely due to variations in height, weight, build, musculature, neck size, and general physique.

That's why we highly recommend making a muslin test or a "practice" garment of some kind (other than to familiarize yourself with its construction, that is!) - you can make the necessary sizing observations (e.g. sleeves need to be an inch longer, waist needs to be loosened, neckline needs to be taken in a bit, etc.).

All this fitting does require extra time and effort on the part of the costumer, but the finished garment's custom-tailored look will definitely be worth it!

There are four main aspects of the garment that may need adjustment and the original pattern need be altered: the neckline, the chest, the waist, and the length of the garment (at various places).

Fortunately, these revisions are not difficult to make!

The neckline is, perhaps, the easiest, as it will most likely simply need to be widened or narrowed, and to accomplish this one only needs to adjust the curvature of the neckline on the printed pattern before cutting.

Another aspect of the neckline which may need to be adjusted is the height of the yoke at the center front; depending on the size of one's neck and/or shape of their chest that the corners of the front opening either droop too low or poke upward. (Both of these are sometimes impossible to avoid, such as when one is sitting or reaching upward; we believe casual standing posture is the primary consideration regarding this.)

If, for some reason, your neckline needs to be lengthened in the other direction, it is a simple matter of adding the appropriate length to the shoulder seam on each side.

For instance, if your neckline needs to be lengthened (as opposed to widened, sideways) by ¼", simply add ⅛" to both the front yoke and the back yoke on the neckline side of the shoulder seam.

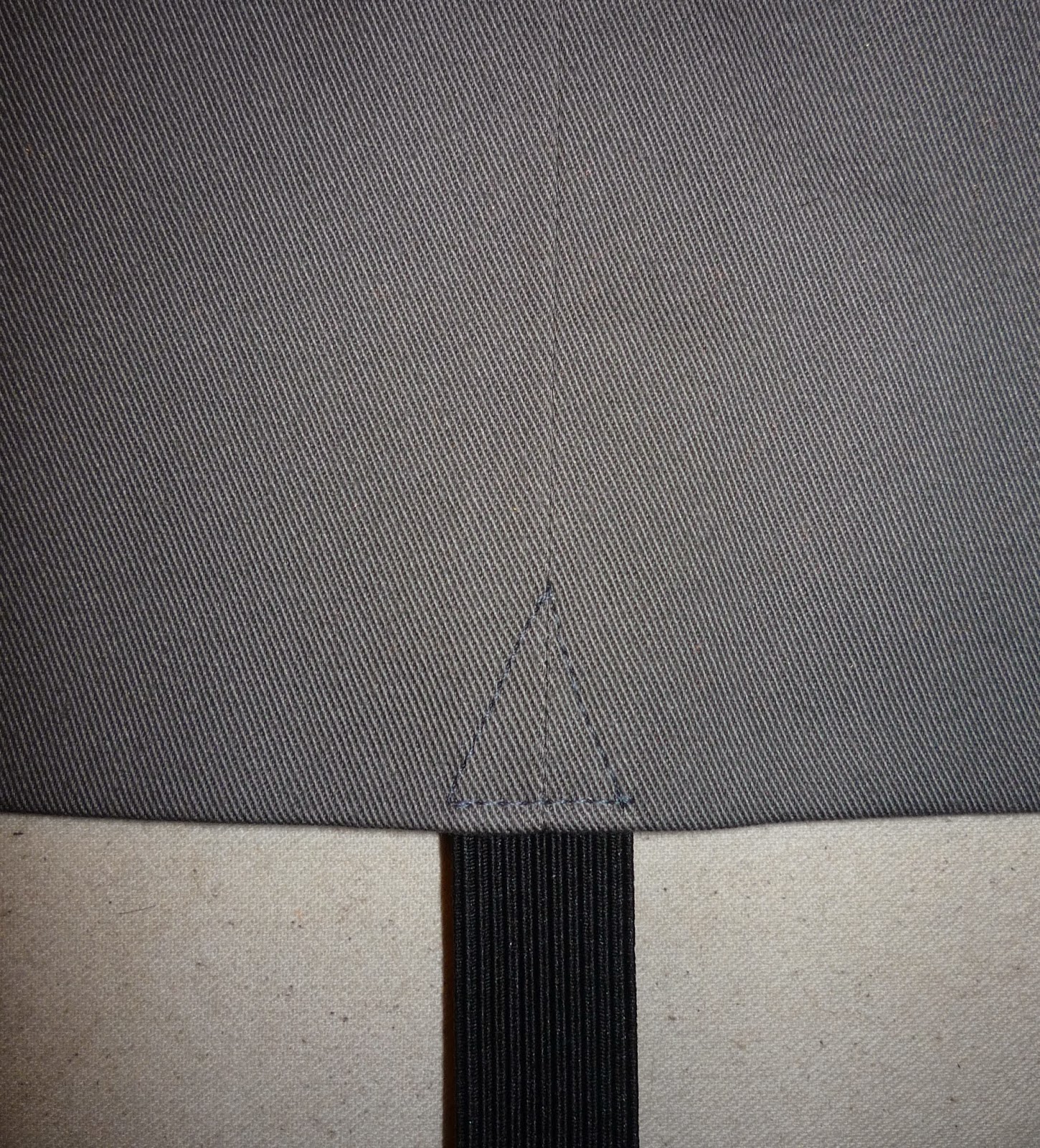

|

| (DS9/NEM duty jumpsuit yoke pictured) |

The opposite would be the case if you need it let out a bit at the shoulder/armscye.

Just remember to adjust the seamline of your shoulder point accordingly!

If you need to adjust the chest, we generally recommend determining the amount of adjustment necessary and distributing it as evenly as possible among the center front/side front and center back body panel seams.

For instance, if you need to let the chest out 2" to achieve a comfortable fit, that 2" could be allocated as ½" to each of the center front/side front body panel seams and 1" to the center back body panel seam. - or, more specifically, by adding ¼" to the outermost edge of the center front body panel, ½" to the centermost edge of the side front body panel, and ½" to the centermost edge of the center back body panel.

This adjustment may need to be made to the entire body panel if one also has a large waist and legs, or one could taper the additional ease from, say, the waist or crotch upward.

Remember, when changing the width of the jumpsuit's body panels, the width of the corresponding yoke piece(s) must also be altered to match!

(In other words, if you let the chest out 2" using the above method, the front yokes will each need to be ½" wider and the back yoke will need to be 1" wider.)

Another option, for minute chest alterations, is the top of the side front/side back seam (under the arm) - adjusting the sleeve (and sleeve lining) accordingly, of course!

The waist is, likewise, an easy aspect of the garment to alter.

Of course, as waist sizes vary widely amongst people, it's also, perhaps, the most likely to need adjustment.

Fortunately, on this jumpsuit, adjusting the waist is a fairly simple matter, as the jumpsuit, without the elastic waistband, is likely quite a bit too large around the waist. The elastic "shrinks" the waist of the jumpsuit body to the wearer to whatever degree is necessary for comfort and mobility.

In most situations, the jumpsuit's waist will be adjustable however necessary by simply adjusting the length of the elastic inside the waistband channel; for instance, if you're using 8" lengths of elastic and the jumpsuit is uncomfortably tight around the waist, try using a 9" or 10" lengths on each side instead.

Alternatively, if you're using 8" lengths of elastic and the jumpsuit is too baggy, try using 7" or 6" lengths on each side instead.

In fact, during your muslin test, you might want to begin with a long cut of elastic - say, 12" - and sew the elastic channel on first over the elastic but only securing the back end of it. Then you can tighten the elastic as necessary by pulling it along the front and pinning, basting, or marking it where the fit is best, cutting off the excess (leaving about an inch "poking out" from the channel, of course) and securing it.

Lengthening or shortening the garment is a simple matter, for the most part.

Naturally, some people will be taller while others are shorter; some may have a long torso and short legs, or vice-versa. Some people may have a long waist and short thighs, while other people may have a tiny "seat" and very long legs. Builds obviously vary considerably!

On the jumpsuit body, there are three places where we recommend lengthening or shortening the body as needed to achieve an ideal fit.

At whichever portion(s) of the body need to be lengthened, cut the pattern along one of the horizontal lines so it is two separate pieces, insert a small piece of paper underneath the two pieces, (a standard 8 ½" x 11" page will work nicely, as well any cheap craft paper you might have sitting around, or you could even put some of that junk mail to good use!), tape the three together, and, making sure the upper and lower portions are properly aligned (i.e. not straight and not crooked/slanted/etc.), use a ruler as a guide and draw a line on each side to connect them. Cut along these lines to form your new, extended pattern piece.

I (Alex), for instance, need to lengthen the upper portion of the jumpsuit body by 1" so it doesn't ride up in the crotch uncomfortably in the front and give me a wedgie in the back (TMI?).

CONGRATULATIONS!

YOU'RE FINISHED!

If you found this tutorial helpful, please support my costume research on Ko-Fi! :)